“You can't manage what you can't measure.”--- Peter Drucker

This quote perfectly applies to real-time tracking in transportation. If you don’t have instant visibility into fleet locations, delivery status, and potential delays, how can you optimize routes and improve your efficiency?

In the logistics industry, every second matters—a five-minute delay can disrupt the entire supply chain. That’s why companies rely on GPS, IoT, Digital Signage, and AI-powered real-time tracking to optimize their schedules.

To fully unlock the benefits of tracking, businesses need the right integrations, predictive insights, and automation to turn raw data into real-time decision-making power.

This article explores how real-time tracking can enhance your supply chain visibility, streamline logistics, and keep fleets running at peak efficiency.

The Role of Real-Time Tracking in Modern Transportation

“Where’s my shipment?”—a question that can make or break your operations.

With rising consumerism and customers expecting faster shipments, real-time tracking is the key to ensuring deliveries happen on time, every time.

Without it, businesses struggle with delays, lost shipments, and frustrated customers—but with the right logistics tracking system, those problems disappear.

Studies show that companies using real-time tracking improve delivery efficiency by 30%. Whether GPS-powered fleet tracking, IoT-enabled shipment monitoring, or AI-driven traffic predictions, businesses now have unparalleled visibility over their supply chain.

For example, a fleet manager can instantly spot a delay, reroute a driver, and notify customers—all in real-time.

But what are some of the other benefits of tracking?

As supply chain tracking evolves, real-time data helps with faster deliveries, lower costs, and happier customers.

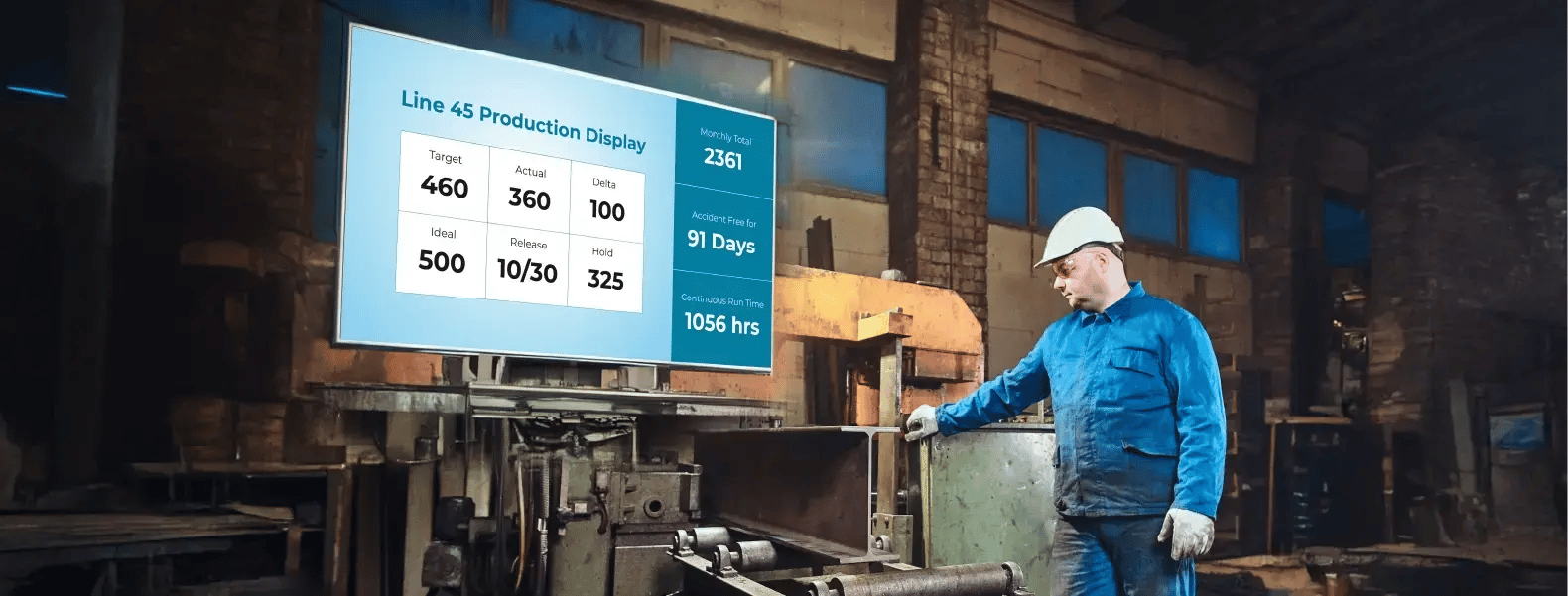

Also Read: How Digital Signage Transforms Real-Time Production Tracking in Manufacturing

Key Features Every Real-Time Logistics System Should Have

Ever had a shipment delayed because of traffic, miscommunication, or lost cargo? Without the right real-time tracking system, your profits can dip due to missed schedules.

The good news? That’s where digital signage steps in.

A well-equipped logistics tracking system removes uncertainty, improves efficiency, and keeps everything running on schedule. But to maximize its impact, businesses need more than just tracking—they need seamless visibility and instant communication integrated with digital signage.

So, what makes a real-time logistics system truly effective? Here’s what makes it work:

- GPS & IoT tracking: Get live location updates on vehicles, shipments, and inventory to avoid unnecessary delays

- Geofencing alerts: Set virtual boundaries that trigger notifications when a shipment enters or exits a designated area

- AI-powered route optimization: Reduce fuel costs and delivery times by automatically selecting the fastest, most efficient routes

- Automated notifications: Keep drivers, warehouse staff, and customers informed in real time with instant updates

- Cloud-based data storage: Access tracking history, performance reports, and live dashboards from anywhere

- Digital signage for live updates: Display real-time shipment locations, route adjustments, and warehouse inventory directly on screens across logistics hubs, ensuring instant visibility for everyone involved

With these features, real-time logistics tracking becomes smarter, faster, and more reliable. Digital signage makes this data instantly accessible—keeping drivers, warehouse teams, and dispatch centers aligned without relying on emails or calls.

Want to see how real-time tracking metrics on your digital signage can transform your logistics?

Book a demo today and experience the difference.

How Real-Time Tracking Improves Supply Chain Visibility

Think of running a logistics operation without knowing where your shipments are, when they’ll arrive, or if delays are coming.

Sounds like a nightmare, right?

That’s exactly why real-time tracking is a breakthrough for supply chain tracking—it provides live updates, predictive insights, and complete transparency over every moving part.

Here’s an industry use case that highlights this:

Use Case: Avoiding Costly Delays

A retailer awaiting a high-demand shipment risks delays without real-time tracking. If a truck gets stuck in traffic, managers and the rest of the delivery fleet remain unaware. With a logistics tracking system, managers get instant updates, enabling reroutes, team notifications, and stocked shelves—all in real-time.

Here are the primary benefits of tracking systems:

- Eliminates blind spots in the supply chain: Gain complete visibility into shipments, inventory levels, and transit conditions, reducing risks of misplacement or delays.

- Reduces costly delays by optimizing delivery routes: Advanced tracking tools use real-time data to suggest the fastest and most efficient routes, minimizing transit times and fuel costs.

- Enhances coordination between suppliers, warehouses, and carriers: Seamless data sharing ensures all stakeholders stay informed, leading to smoother handoffs and fewer disruptions.

- Improves customer satisfaction with accurate ETAs and proactive updates: Real-time tracking provides customers with precise delivery timelines and alerts them about potential delays, enhancing trust and reliability.

With real-time tracking, businesses aren’t just moving shipments—they’re making smarter, faster decisions that keep the supply chain running seamlessly.

Also Read: Enhancing Productivity Through Goal Visibility: Keeping KPIs Top of Mind for Manufacturing Teams

Overcoming Challenges in Real-Time Logistics Tracking

While real-time tracking appears to be the ideal solution for logistics efficiency, its implementation presents certain challenges. Here’s a quick overview of common challenges faced by transportation companies as well as possible solutions to each:

| Challenge | Solution | |

| Connectivity issues (GPS signal loss, remote area tracking failures) | Use 5G networks and edge computing for uninterrupted tracking, even in low-coverage areas. Display network status and backup plans on digital signage to keep teams informed. | |

| Inaccurate data (delays, incorrect location updates) | Implement AI-driven analytics and IoT sensors to validate and correct tracking data. Show live shipment status and issue alerts on warehouse digital displays for quick action. | |

| Cybersecurity risks (hacking, data breaches) | Encrypt tracking data, secure APIs, and enable multi-factor authentication for system access. Use digital signage dashboards to display system security status and ensure compliance. | |

| Hardware failures (damaged tracking devices, sensor malfunctions) |

|

Also Read: The Role of Real-Time Metrics and Performance Boards in Manufacturing

Optimize Your Logistics with L Squared

As real-time logistics tracking advances, businesses need smart solutions to stay efficient, minimize delays, and maintain end-to-end supply chain visibility.

That’s where L Squared makes a difference.

With 17+ years of expertise, L Squared provides digital signage solutions that enhance logistics tracking systems—helping fleets, warehouses, and supply chains stay connected and informed across distances.

Looking to future-proof your logistics? Contact L Squared today and take control of real-time tracking like never before!

Frequently Asked Questions

1. What is real-time tracking of delivery?

Real-time tracking of delivery refers to the ability to monitor shipments, fleet movement, and delivery progress as they happen. It provides businesses and customers with instant updates on the location, estimated arrival time, and potential delays. Digital signage enhances this process by displaying real-time tracking updates in warehouses, logistics hubs, and dispatch centers, ensuring seamless coordination.

2. What is an example of a real-time tracking system?

A common example of a real-time tracking system is GPS-enabled fleet tracking, where transportation companies use GPS and IoT sensors to monitor vehicle locations, optimize routes, and predict arrival times. These systems often integrate with digital signage, displaying live tracking data across logistics centers, helping teams react quickly to delays and reroute shipments when necessary.

3. What is tracking in transportation?

Tracking in transportation involves monitoring vehicles, shipments, and inventory throughout the supply chain. It ensures that logistics operations remain efficient, deliveries stay on schedule, and resources are optimized. Digital signage plays a critical role by broadcasting real-time logistics updates, alerting drivers and warehouse staff about route changes, traffic conditions, or unexpected delays.

4. What technology is used for real-time tracking?

Real-time tracking relies on several advanced technologies, including:

- GPS and IoT sensors – For precise location tracking and shipment monitoring

- AI-powered route optimization – To minimize delays and improve efficiency

- Geofencing – To trigger location-based alerts for shipments entering or leaving designated zones

- Cloud-based data analytics – For tracking history, predictive insights, and reporting

- Digital signage – For live updates on shipment movement, fleet performance, and warehouse inventory, ensuring instant visibility across logistics operations

5. What is GPS tracking in logistics?

GPS tracking in logistics enables companies to monitor fleet movements in real-time, reducing inefficiencies and improving delivery accuracy. It helps transportation managers reroute vehicles, track delays, and maintain supply chain transparency. When combined with digital signage, GPS tracking ensures that logistics teams receive instant updates on shipment status, allowing for proactive decision-making and reduced downtime.