Every manufacturing operation is a race against time.

Real-time data display empowers you to make fast, accurate decisions, putting you in control of your operations. Without it, you risk falling behind and losing that control.

With real-time data display, you can shift from firefighting to proactive management, relieving the stress of constantly reacting to issues.

And when manufacturing errors and delays cost money, the stakes couldn’t be higher.

The Hidden Cost of Not Using Real-Time Data

Without real-time data display, manufacturers are often flying blind.

Systems can go unnoticed, production bottlenecks can linger undetected, and quality issues can slip through the cracks until too late.

Delayed responses to issues result in more downtime, wasted resources, and higher operational costs, and the consequences quickly snowball.

A factory floor with delayed data is a factory floor where problems are discovered too late to fix efficiently.

Having real-time data at your fingertips can minimize equipment failure, unexpected downtime, and safety violations.

That’s where L Squared’s real-time data display solutions come in. They ensure you’re always in the know and proactively address issues before they escalate.

Real-Time Data Display: Improving Efficiency, Minimizing Errors, and Supporting Continuous Improvement

Real-time data display helps you catch problems before they snowball, giving you instant visibility to fix issues and optimize operations on the spot.

Real-time monitoring for efficient operations

One of the biggest pain points in manufacturing is the lack of visibility.

Without real-time insights, workers, managers, and teams must decide based on outdated or incomplete data. This leads to inefficiencies that compound throughout the production cycle.

This problem is solved with real-time data display. Immediate visibility into every aspect of the production line—machine performance, inventory levels, or worker progress—means fewer bottlenecks and faster decision-making.

For production supervisors, it means better resource allocation and reduced downtime. For operational leaders, it means improved process efficiency and quality control. And for plant managers, it means enhanced overall operational performance.

Production schedules can be adjusted instantly based on real-time data, minimizing delays and ensuring tasks are completed on time.

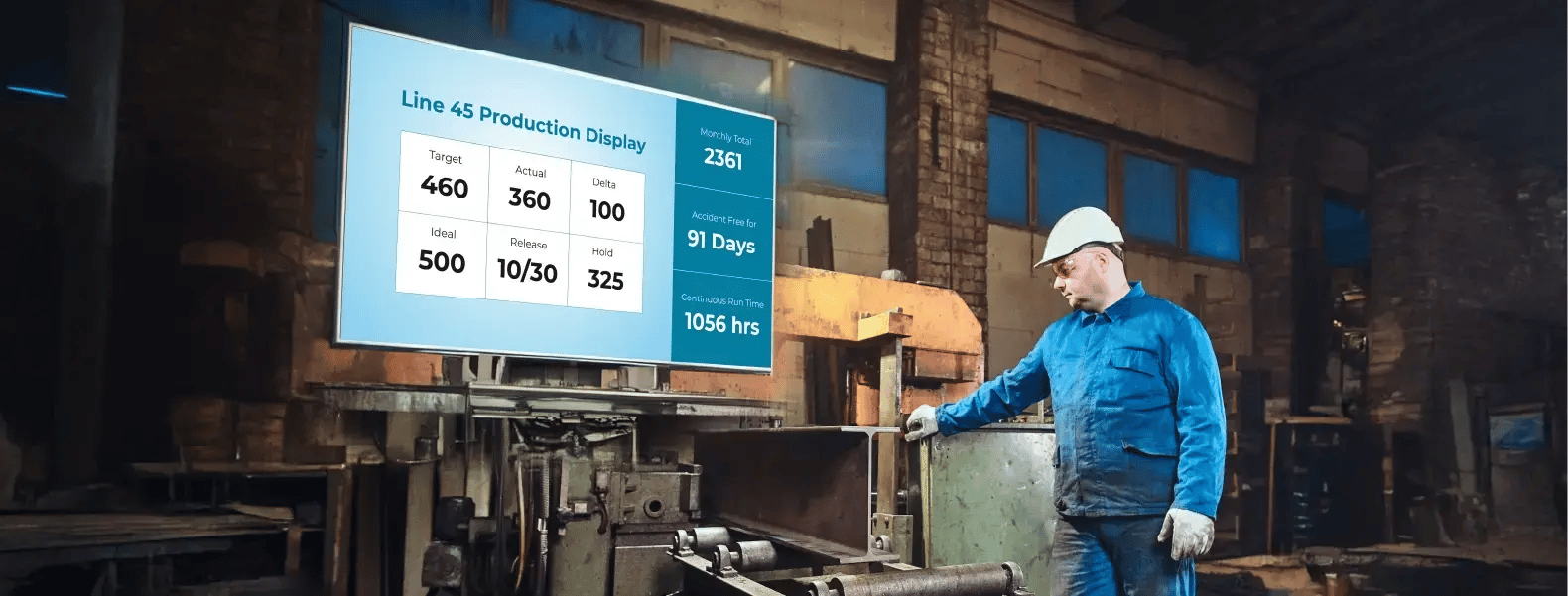

For example, manufacturers can use L Squared’s digital signage software to track machine performance and production speed across the floor in real-time production tracking.

This constant monitoring helps identify issues in real-time, giving workers the insights they need to optimize output and adjust operations.

Minimizing downtime and errors

Real-time data display allows for detecting minor issues before they become major failures. Imagine receiving an instant alert when a machine shows signs of inefficiency—this would enable maintenance to address the problem before it causes downtime.

Manufacturers can maximize machine uptime by reducing unexpected shutdowns and ensuring smooth production runs.

Real-time data display also plays a key role in minimizing human error. With up-to-date information always visible, workers are less likely to make mistakes.

Data discrepancies are caught immediately in a setting where accuracy is essential, preventing costly mistakes from slipping through the cracks. A good example is how real-time displays can help maintain manufacturing compliance across multiple shifts, ensuring that operators across different shifts adhere to safety protocols without room for error.

Supporting continuous improvement

Manufacturing thrives on continuous improvement, and real-time data display is a crucial tool in driving this mindset. Installing data from every part of the operation allows teams to analyze performance continuously, identify inefficiencies, and make real-time improvements.

For example, managers can quickly identify underperforming areas by monitoring production output and comparing it against targets. Instead of waiting for weekly or monthly reports, they can access immediate data to take corrective action immediately.

Responding in real-time enhances speed and effectiveness when shifting resources, adjusting production schedules, or addressing equipment performance.

Moreover, real-time data display fosters a culture of accountability and transparency. When everyone has access to up-to-date data, it encourages teams to take ownership of their roles and results. This helps improve efficiency and drives engagement, as workers can directly see the impact of their efforts on production.

Why Real-Time Data Display is Non-Negotiable for the Future of Manufacturing

Manufacturing is rapidly evolving, and the demand for faster, more accurate, and more efficient operations is only growing.

The key to staying competitive is leveraging real-time data display to make smarter decisions, reduce errors, and foster continuous improvement across all operations.

Adopting real-time data display in your facility will improve efficiency and future-proof your operations. By embracing real-time data, you’ll be better equipped to adapt to changes, respond to problems immediately, and continuously optimize production.

The future of manufacturing is data-driven. Companies that use real-time data display will gain a significant competitive edge and drive operational success for years.

Ready to Take the Leap into Real-Time Data Display?

Manufacturing is evolving, and those who can access data as it happens will thrive. However, you'll be behind if you’re still relying on outdated systems and delayed reporting.

With real-time data display, your operations will become more responsive, your team more efficient, and your products higher quality. Start small, scale up, and experience the transformation in your manufacturing processes.

Ready to explore how L Squared’s real-time data display can improve your operations? Book a demo today and see the difference for yourself.